Quality Management

Satisfied customers are our main asset. To help PURPLAN ensure the highest quality and viability of every contract job, we bank on consistent Quality Management in our company, because innovative construction of installations from the first step of planning and assembly till the systematic maintenance can only be successful if all departments of the enterprise work together at the highest level transparently and according to clearly defined standards.

Quality Management comprises mainly four spheres: after thorough analysis of all working areas the quality planning chalks out feasible concepts and procedures for the fabrication of highly complex plants. The quality administration takes care of smooth implementation of these concepts. Continual evaluation of quantitative and qualitative indicators ensures the quality of planning and production procedures. But only stringent quality controls make sure that with every new project the construction of an installation by PURPLAN can be continually developed and that our customers can always expect state-of-the-art technology from us.

We can achieve such high standards only through excellent engineering personnel on the staff: regular advanced study and training programmes and in-house Human Resources Development programmes for our employees are, therefore, a matter of fact at PURPLAN.

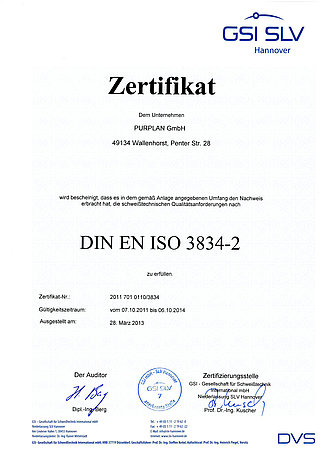

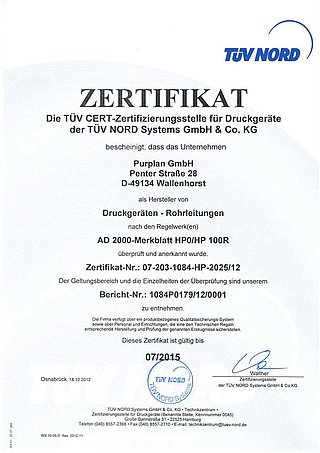

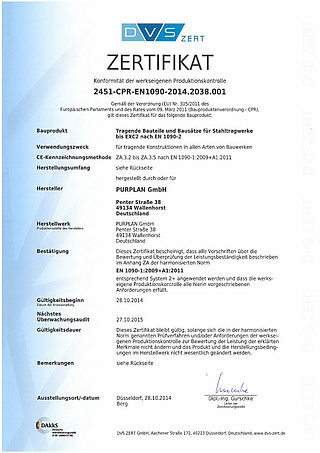

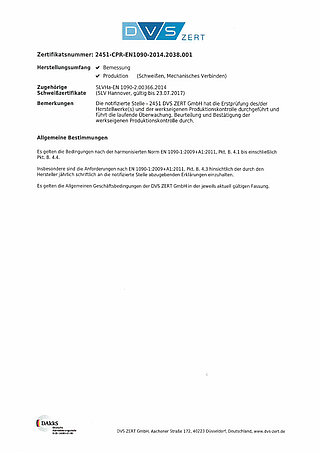

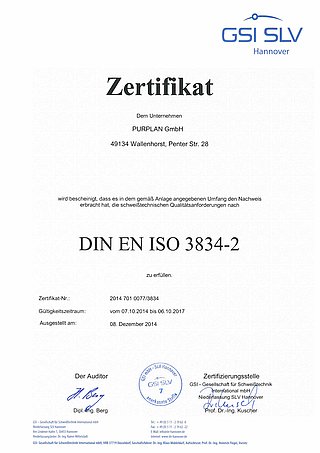

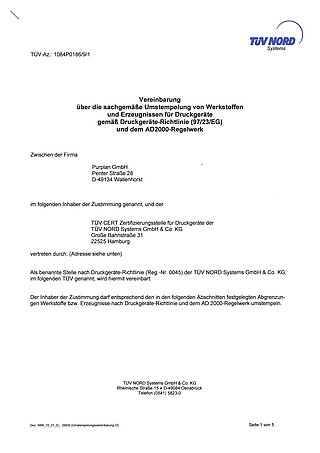

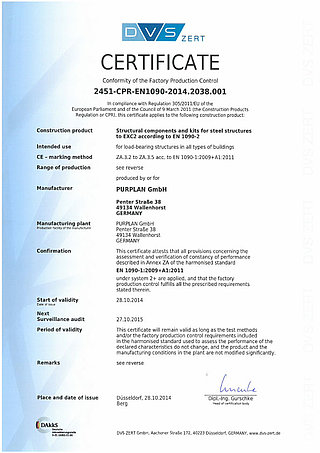

Our customers need not only depend on mere words when it comes to the quality of work performed by PURPLAN. Manufacturers' qualification, HPO permission, process verifications and certification of our welders speak for themselves and, our certificates and approvals are a proof of this. Convince yourself of it.