Maintenance objectives:

Ensure the necessary technical system availability according to the "just enough" principle:

- Any reduction in availability disrupts production goals.

- Any increase in availability results in unnecessary additional costs.

Ensure that production facilities are:

- Technically reliable

- Environmentally friendly

- Economical

- Quality-assured

Maintenance measures must be efficiently ("doing the right things right") and cost-consciously planned and implemented!

Our service products

Repair

Demand-driven troubleshooting after equipment failure.

Inspection

Planning, execution, and documentation of testing and inspection work to determine and assess the current condition.

Maintenance

Planning, execution, and documentation of preventive maintenance measures (independent of conditions at specified time intervals or condition-oriented depending on component wear).

Improvement

Planning and implementation of measures to optimize maintenance processes:

- Development of a demand-driven (risk-based) maintenance strategy.

- Conducting vulnerability analyses and implementation of derived measures.

- Potential analyses for autonomous maintenance.

FAQ

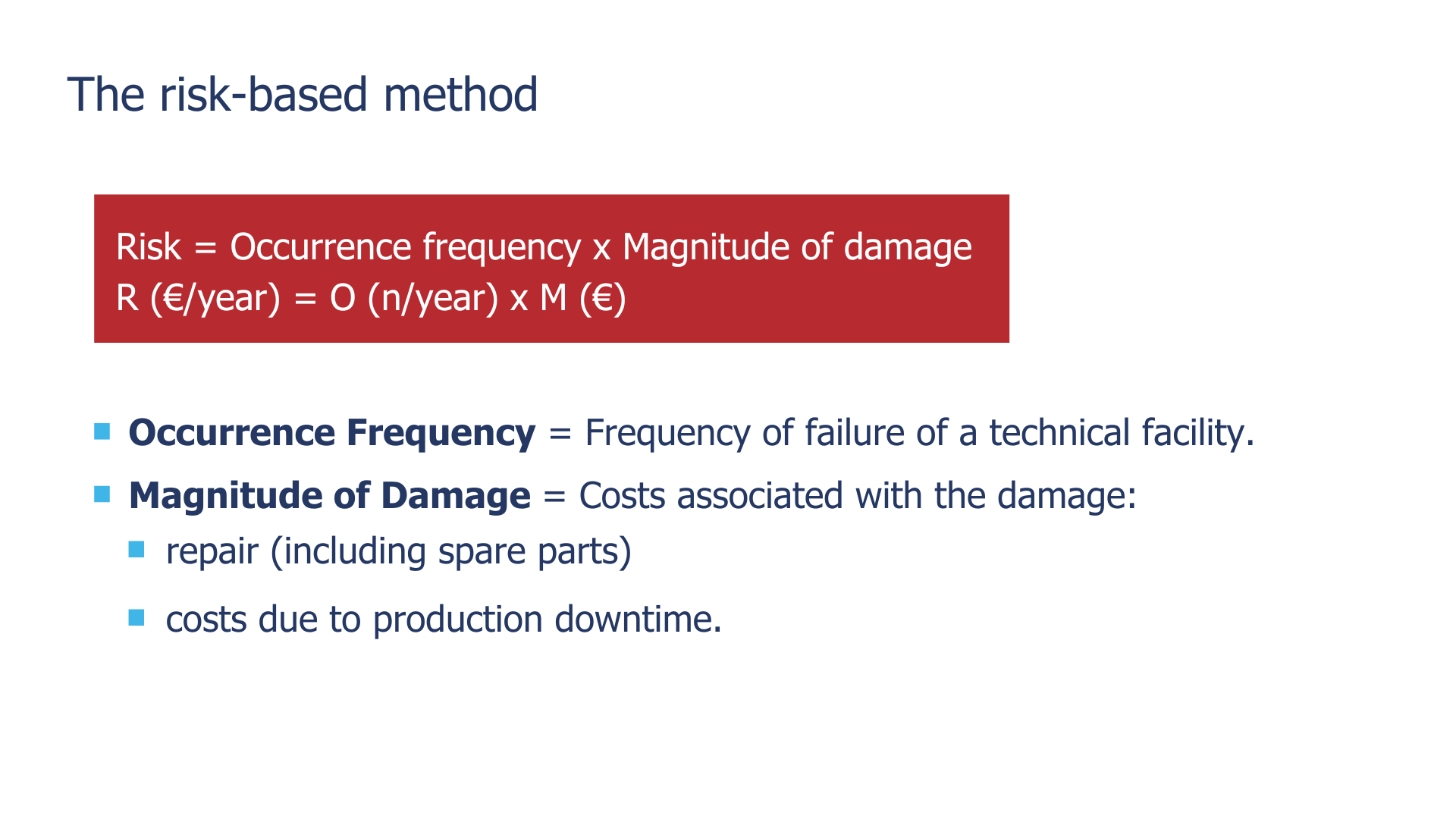

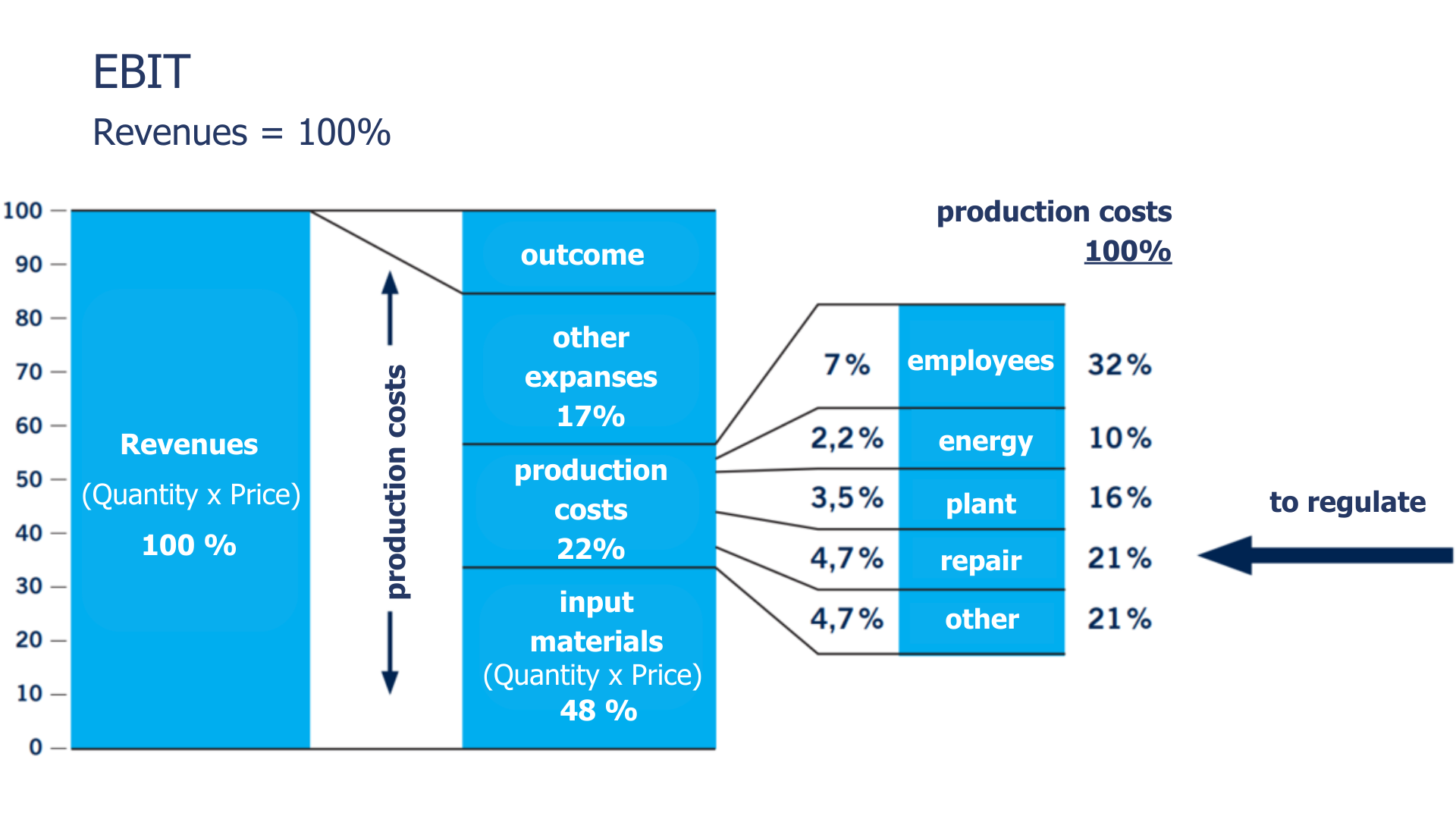

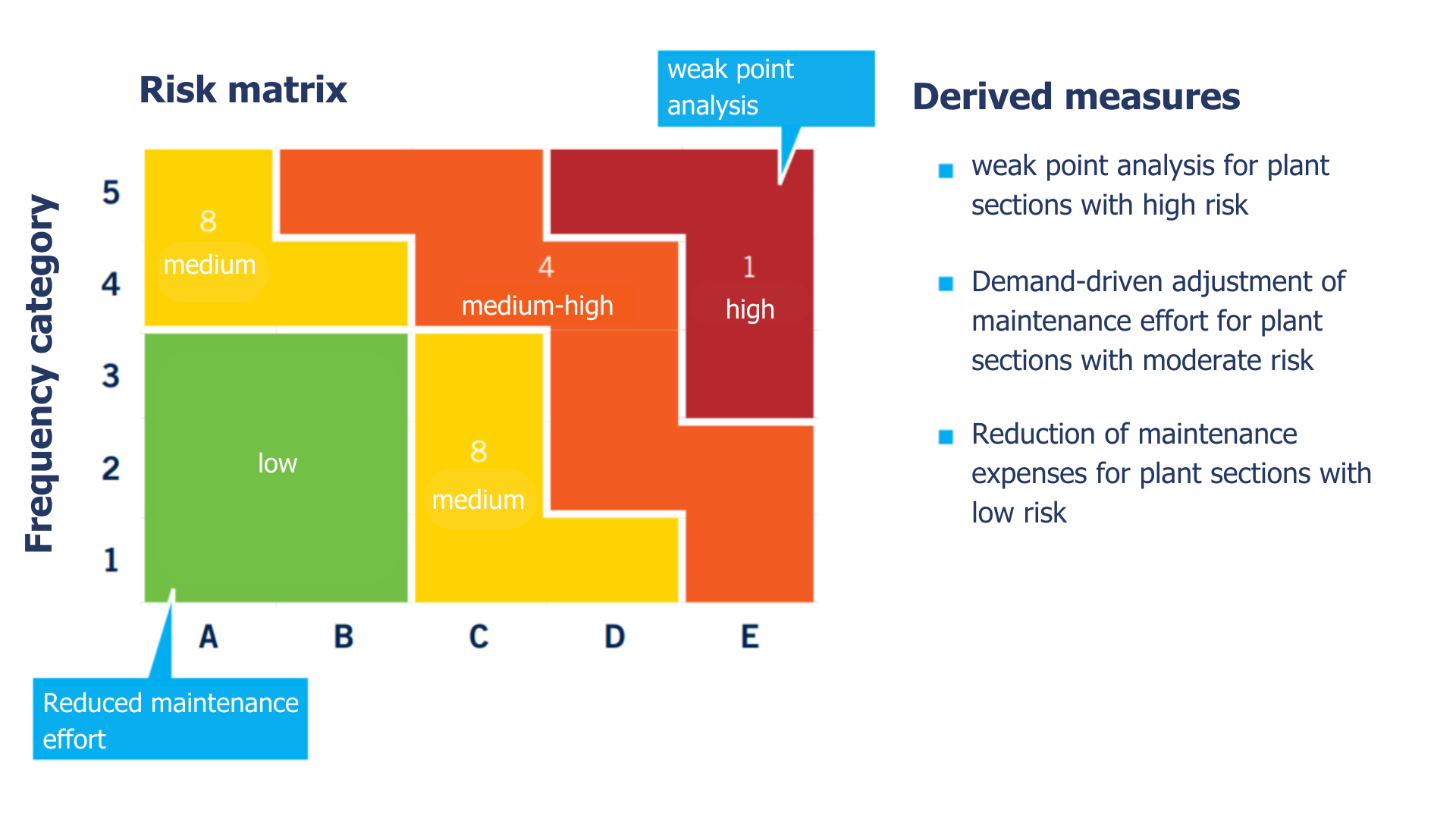

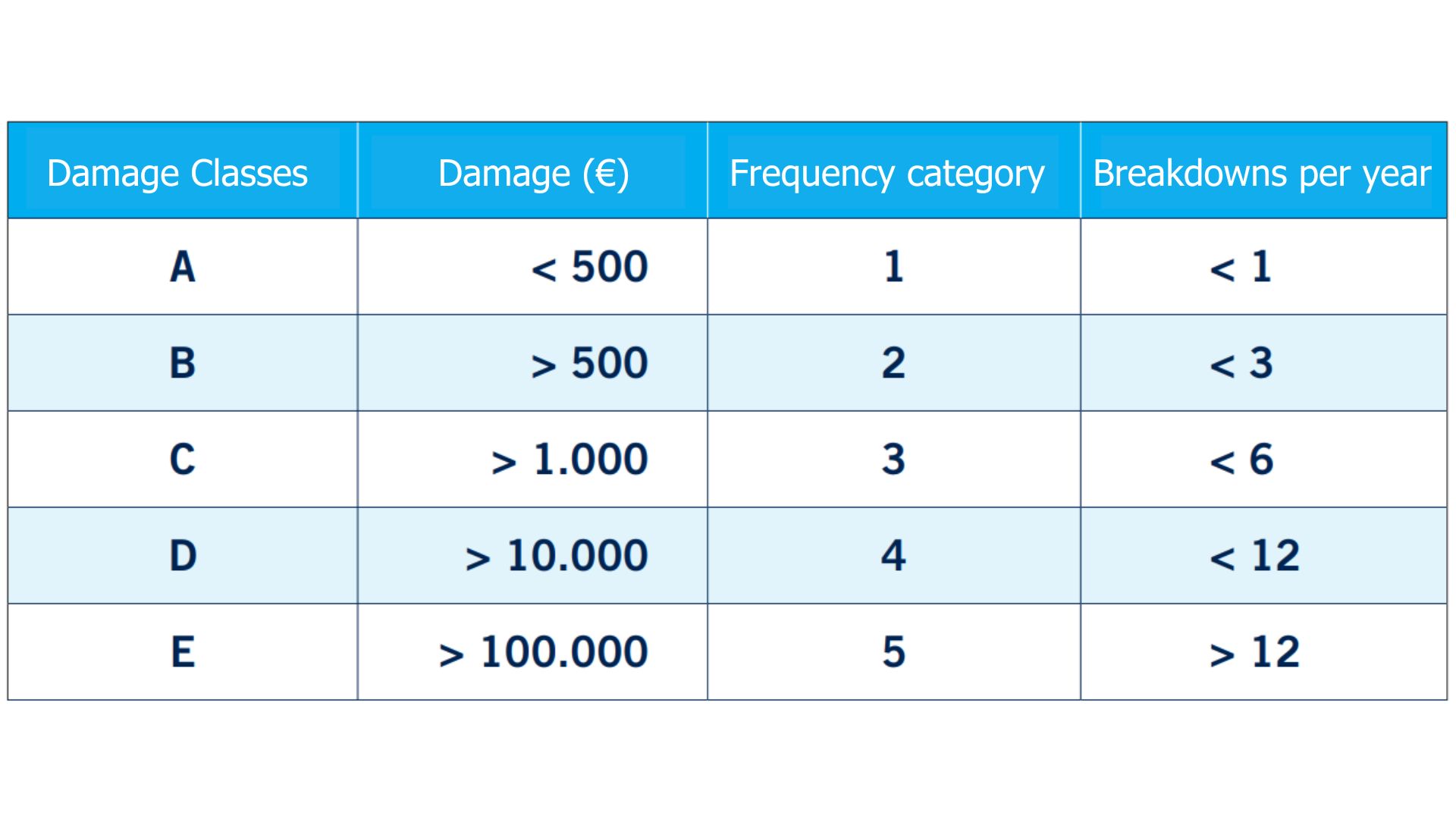

RBI stands for Risk-Based Inspection. In this maintenance strategy, component failures in production facilities are recorded and evaluated in a risk matrix based on their failure frequency and failure costs (for repair and production interruption).

RBI enables the assessment and control of maintenance costs to achieve sustainable cost savings.

Depending on the defined risk level, maintenance efforts are optimized according to the "just enough" principle.

To calculate more precise cost savings for your operation, please feel free to contact us.

PURPLAN assists the customer in creating and evaluating the history of equipment failures. The failure data collected by the plant operator are transferred to and assessed by PURPLAN in a risk matrix. PURPLAN provides targeted suggestions on how to reduce maintenance efforts in the future.

For each plant that Purplan distributes, a template for collecting failure data is provided to the customer free of charge.

The engineering services for the creation and evaluation of the risk matrix are billed on a time and materials basis. The customer will receive a project-specific quotation for these services.